A quick minute of today’s activities. (3 hives taken to the bee yard, checked hives from the splits I made on Saturday, and responded to an emergency swarm call in Allen, Tx)

|

||||||

|

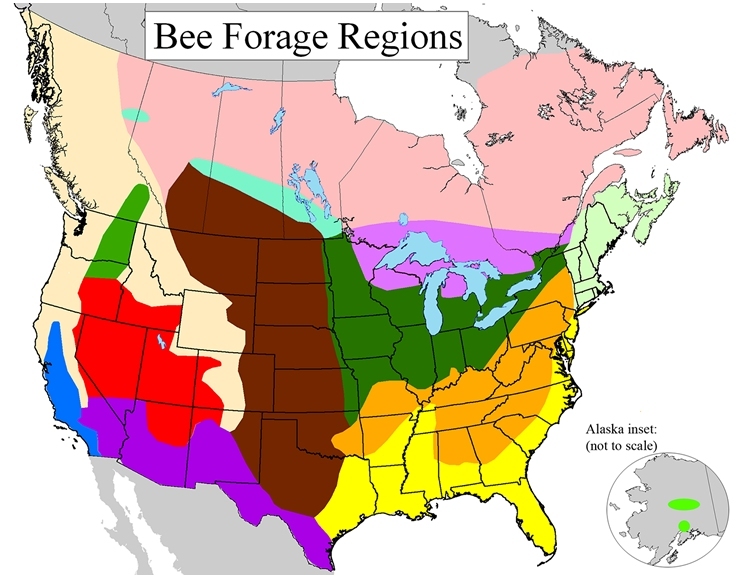

I pulled the excess honey from 4 hives today. Yes.. 4 hives. Some of my friends know the math on the box weight…. Take a wild guess as to the weight of the boxes/honey. All hives that were doubled up with brood (2 deeps high) were split. The hives with the highest population showed signs of wanting to swarm soon (open queen cells, with royal jelly & developing queens in them) – so I gave them room, and created new hives with the 2nd box of bees – making sure to provide queen cells so they can have a mated queen laying eggs ASAP. These gentle ladies needed a new home so that the homeowners could put their house on the market to sell. I had a helper on this one- who shows a promising future in beekeeping. The valve box was almost 2′ deep, and there was a LOT of capped brood. I’ll leave the box for a few days, then take it to the bee-yard. A North Texas leathercrafter contacted me for beeswax earlier in the year. His intention was to use it in a recipe as a leather conditioner and waterproofing (or water-resistant) agent. He used beeswax, and softened the wax with Neatsfoot oil. You can find recipes to fit your needs in many publications or online. Here’s his results: 1 House, 2 Hives. According to the neighbors, both of these hives have been in existence for well over 10 years. I believe it – with the hard, black propolized comb. Both hives were in the joist space between floors of a 2-story home. Hive #1 had bees that were very gentle to work with, and had lots of honey that they had stored. They were accessed through the drywall below the hive. Hive #2…(2nd two pics) – well, they weren’t so nice. (they were accessed from above – through the 2nd floor decking). These bees have survived a Texas summer, fall, and now a winter. The homeowner says that the bees moved in the BBQ pit last spring. The bees were not bothering anyone – so they let them stay for a while. Before springtime sets us in with warm weather, though – the bees *really* need to be hived into a proper hive. Though I took away the bees today (28 degrees, snow, ice, etc) I’ll take them to the bee-yard, and when temperatures are warm enough for a proper removal and transition to a commercial hive, I’ll spend about 2 hours with their move to a regular box. (If you look closely at the 2nd picture, you might see a few bees poking their heads out to see what I was doing). NASA has collaborated to provide information to (and from) beekeepers to show nectar flow data. Their resource lists plants in a large region, as well as whether those nectar sources are a significant forage item for the bees, or if it is not. A guesstimation is also given as to what months the particular plants are in bloom for a nectar flow. A link to the USDA website is also provided in the regional (state) maps that you can click on – and search the database for specific plant data.

The link is HERE for the information. Over 10 years ago, I started, marketed, worked, built, and completely ran (with an occasional helper) a company dedicated to building storage sheds in the Dallas metroplex. The photos below are one of the larger buildings that I built – that was later renovated to be a back-yard apartment. The construction photos below show the process up until the point that the city approved the building as built per their issued permit for a “portable building /outbuilding /storage shed”. All rules and laws were adhered to by me for the construction of this building. After the permit / inspection approval… the homeowner contracted with “someone” for some additional upgrades to the structure. 16×20 Organizer – Built by Rex Smith

|

||||||

|

Copyright © 2024 Harmony Hollow Apiaries - All Rights Reserved Powered by WordPress & Atahualpa |

||||||